Pharmaceutical Company

(Schering-Plough Summit, NJ)

SCOPE OF WORK:

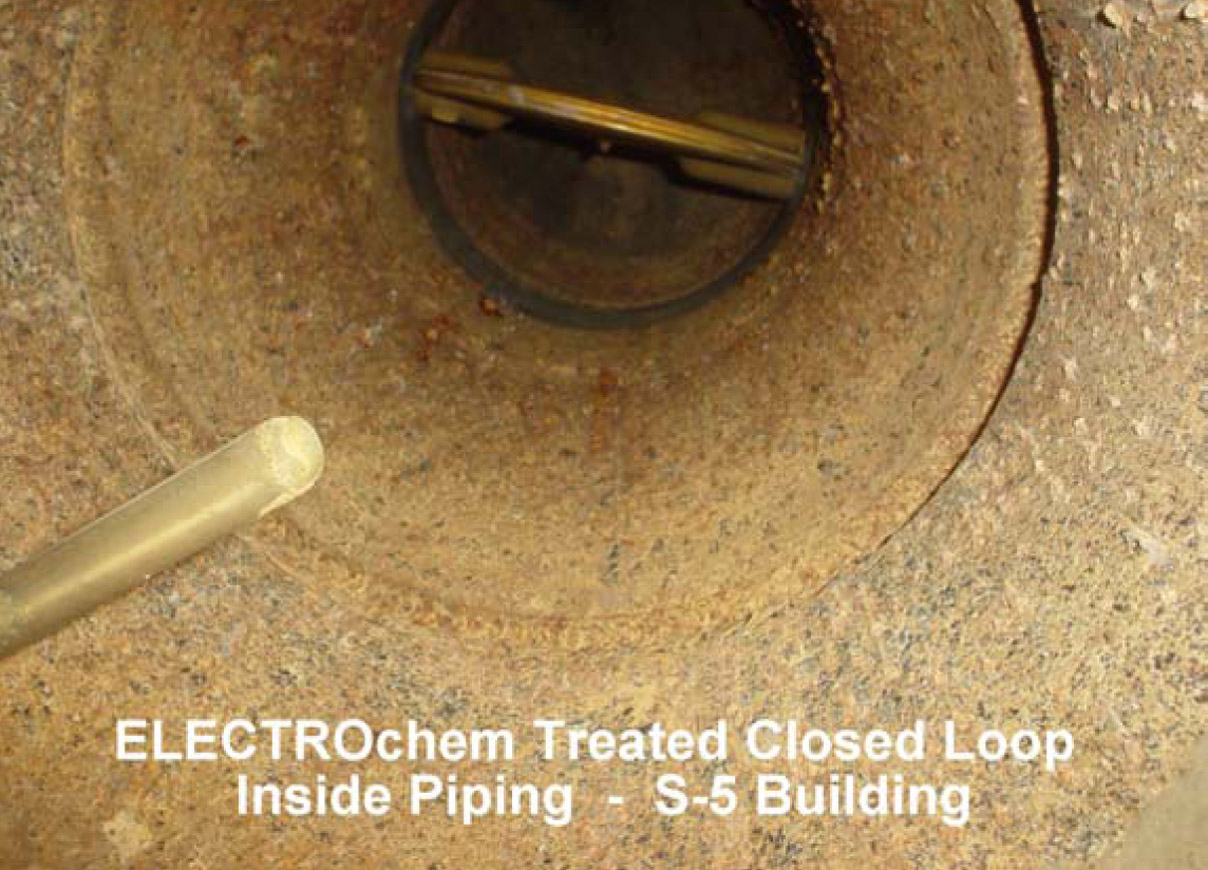

ELECTROchem Water Treatment vs Traditional Chemical Treatment

CUSTOMER:

Schering-Plough, Summit, NJ

FACILITIES:

Bldg S4, S5 and S10

HISTORY

For clarification, S4’s chiller system is operating with both ELECTROchem and traditional chemical treatment; S5’s chiller system is a 100% ELECTROchem treated system; and S10, which is also a 470-ton chiller, is 100% traditional chemical treatment. In the spring of 2007 ELECTROchem installed their water treatment system in Schering-Plough’s S5 building on a 470-ton York chiller. ELECTROchem’s system has been operating for the past two years.

S4 also received an ELECTROchem water treatment system in 2007 that was installed on two 470-ton chillers; however, ELECTROchem was asked to turn the entire system off after several months of operation because of contract concerns with the chemical treatment company.

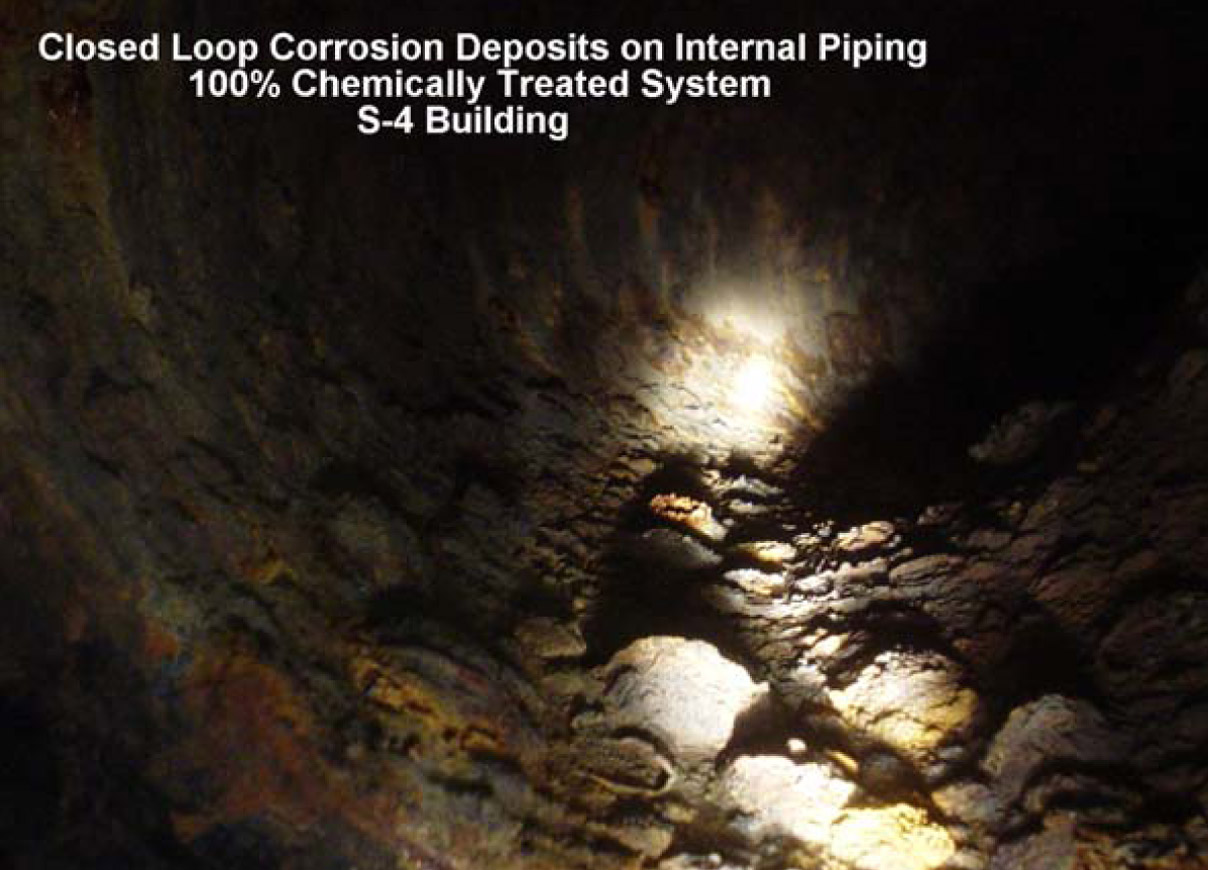

In the fall of 2008 the S5 and S4 chillers were opened and inspected. Only the S5 chiller with 100% ELECTROchem treatment was virtually scale-free. Photographs show S4’s chillers had considerable scale even after the tubes had been punched. Pictures were also taken of S5’s cooling tower, with the clear water, that was serviced by ELECTROchem, and S4’s tower, with the green algae, that was serviced by the existing chemical company.

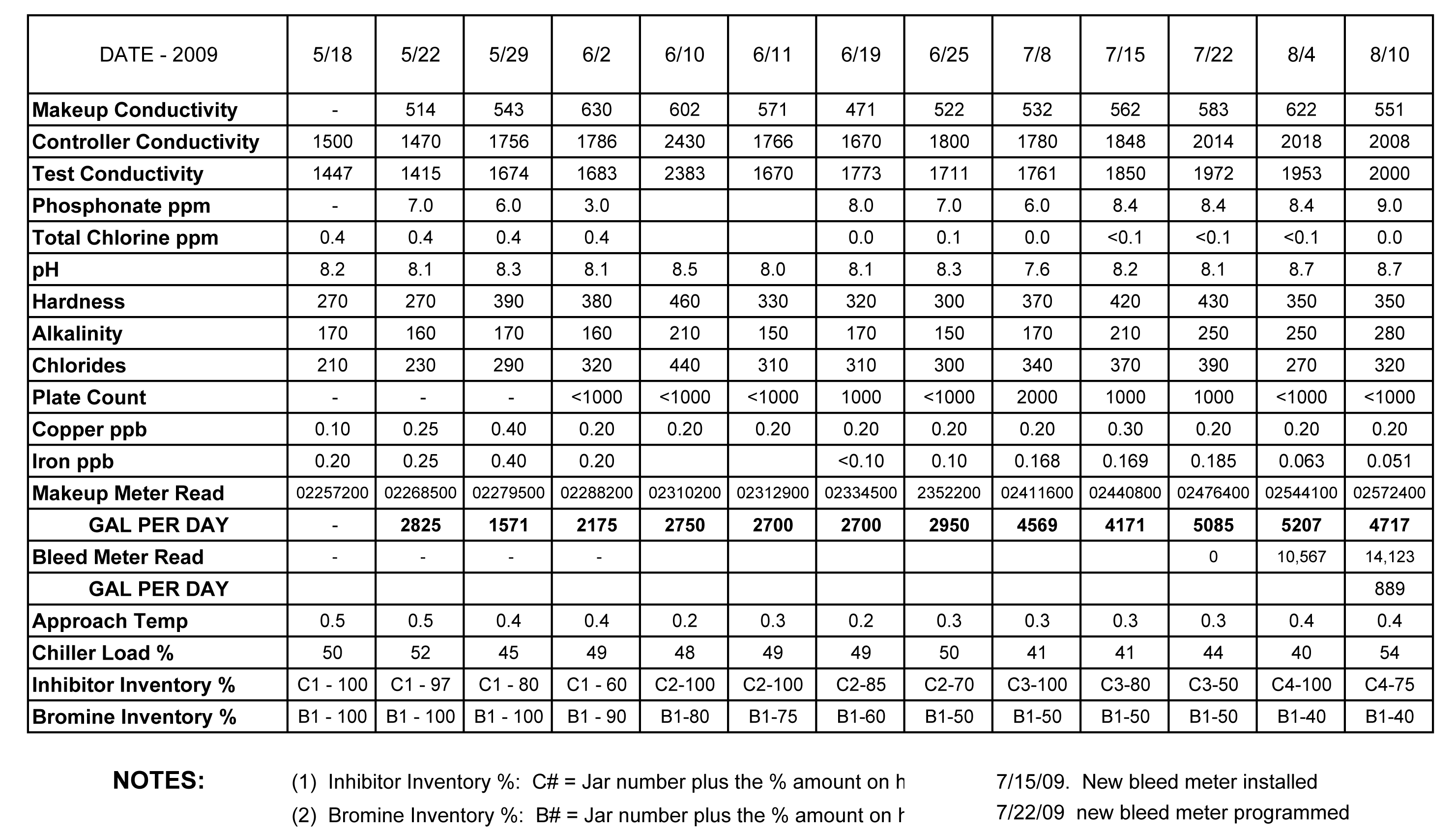

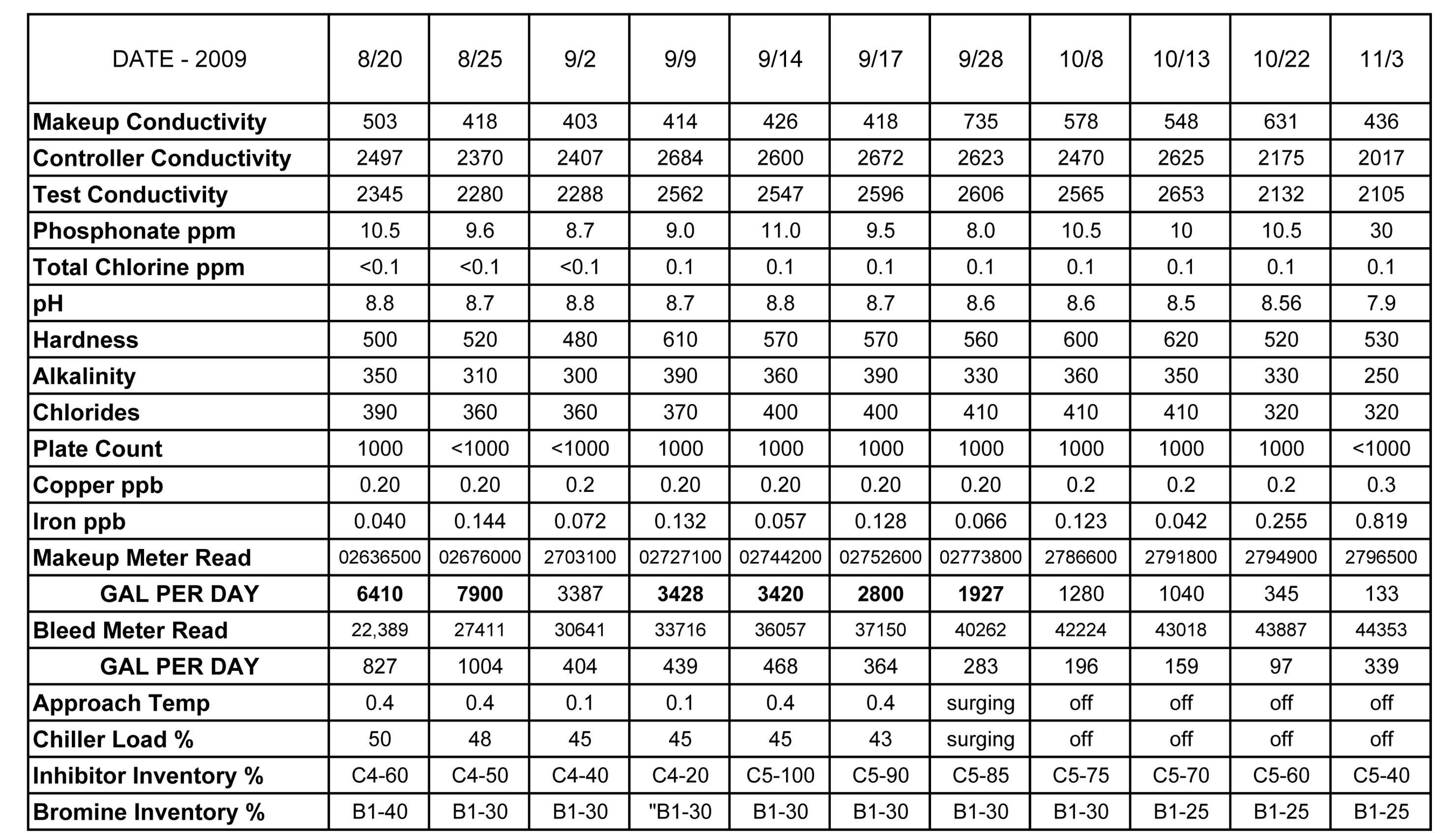

In 2009 an independent water treatment consultant was hired to evaluate ELECTROchem’s water treatment system versus the existing traditional chemical treatment system. ELECTROchem provided monthly service to S5 that included inspections, water analysis, corrosion coupons and monthly testing for biologics. ELECTROchem also monitored S4’s system that was turned on; however, the existing traditional chemical treatment in this facility was also left in place.

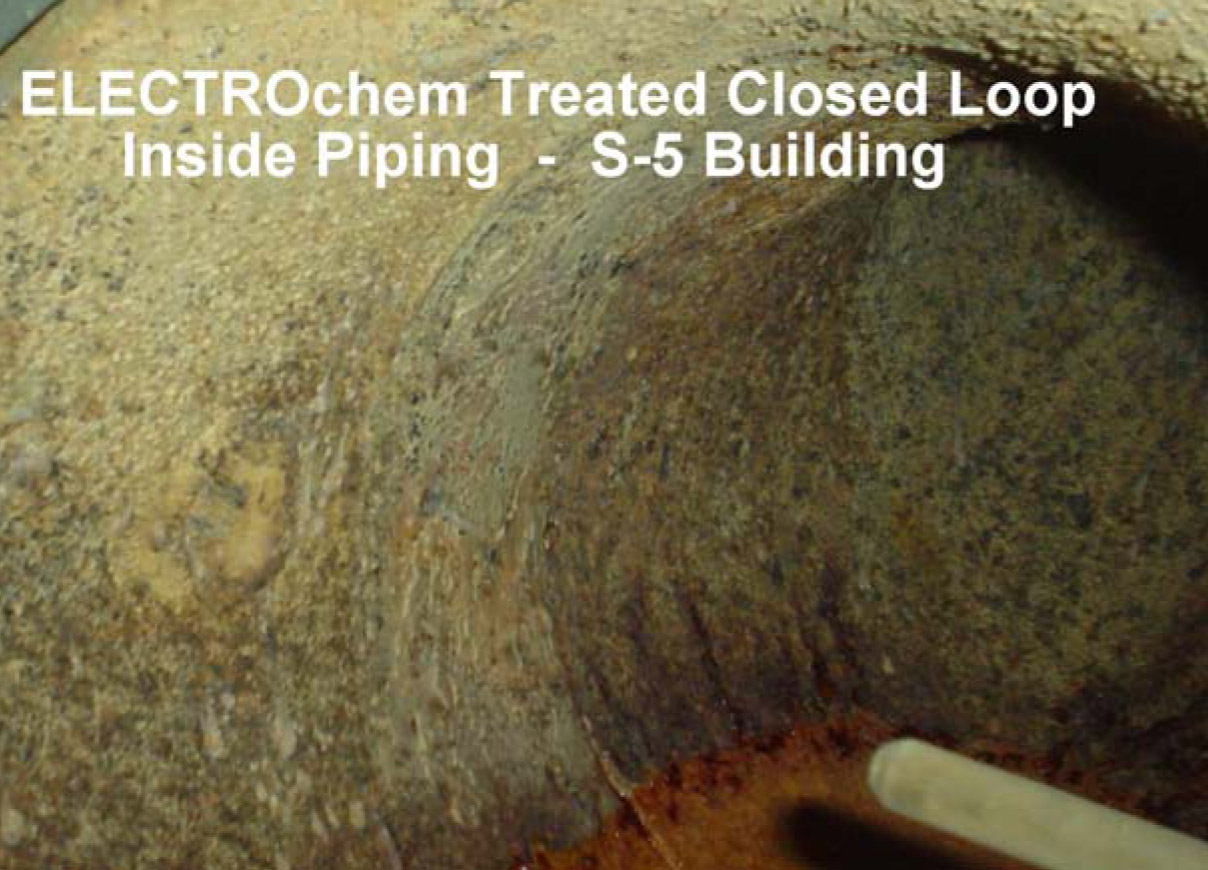

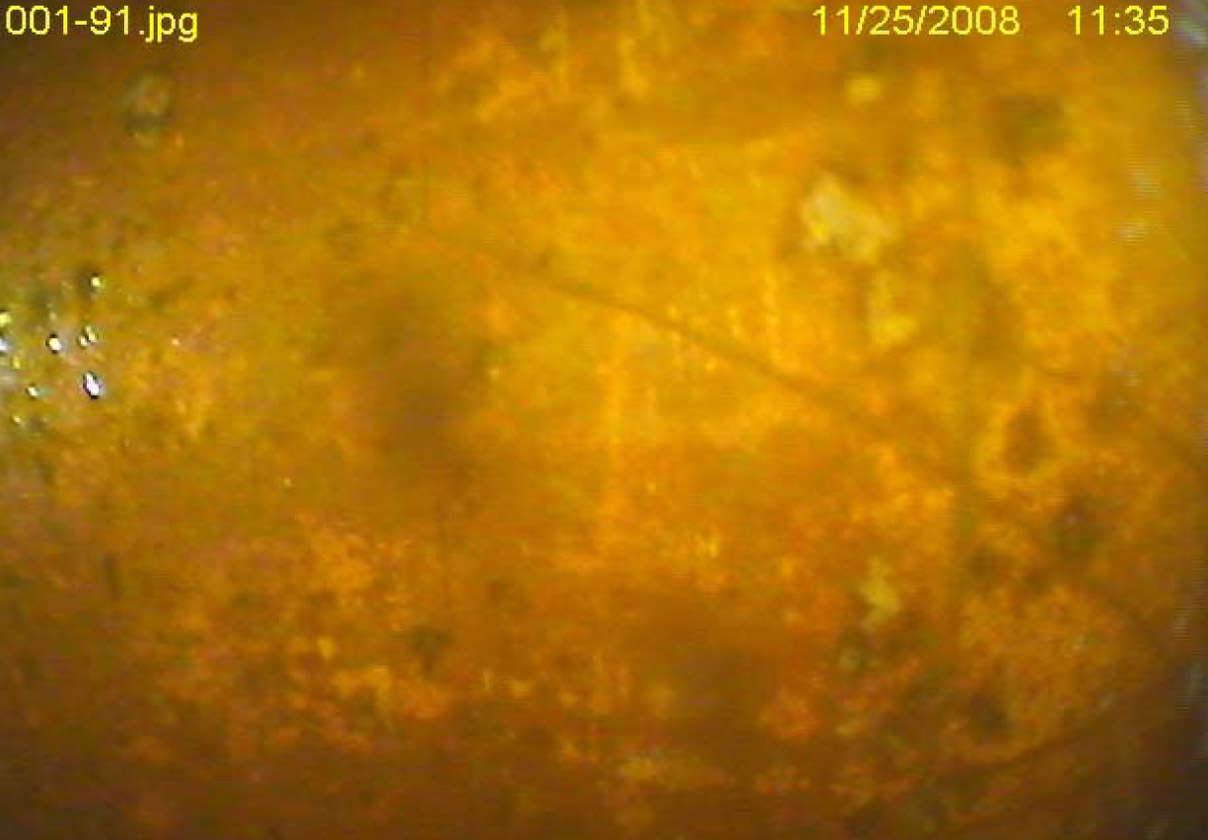

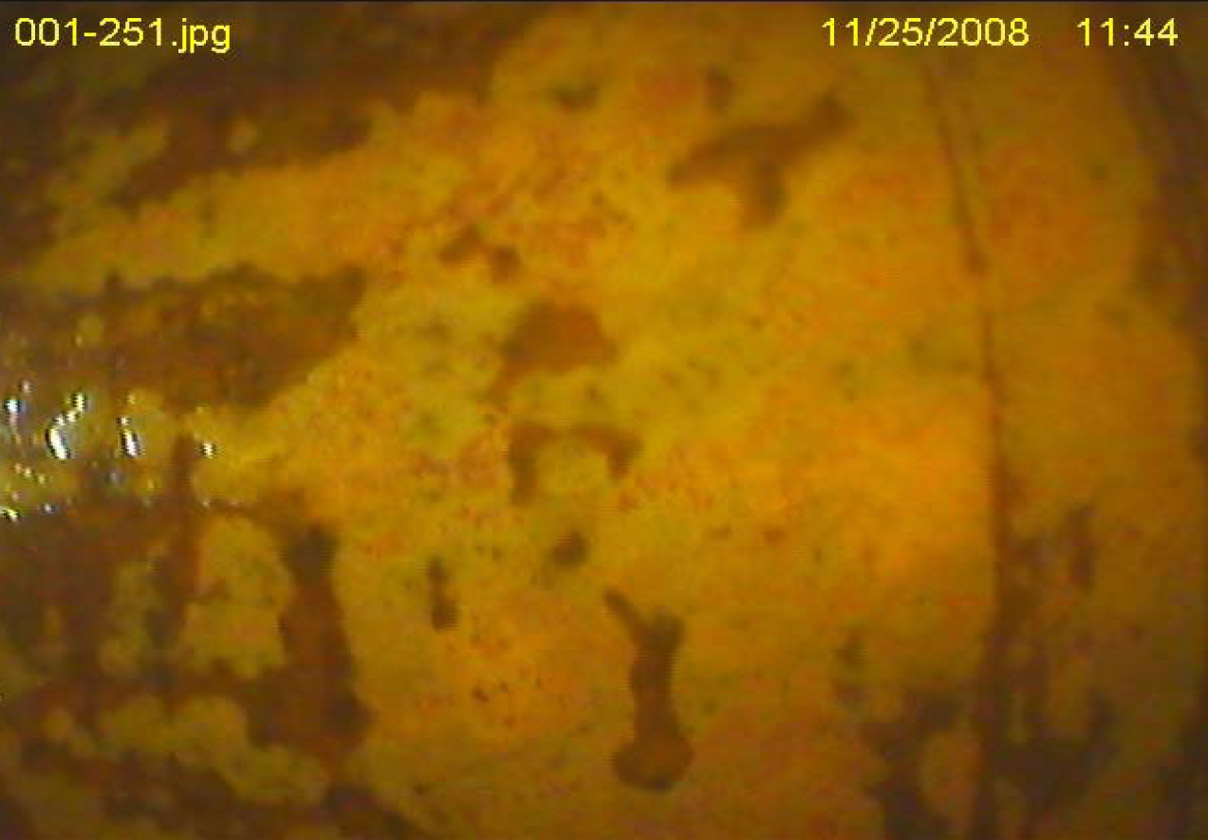

For test purposes borescope pictures were taken in December 2009 of the S4, S5 and S10 facilities prior to any tube cleaning. For clarification, S-4 is operating with both ELECTROchem and traditional chemical treatment; S5 is a 100% ELECTROchem treated system; and S10, which is also a 470-ton chiller, is 100% traditional chemical treatment. Pictures were also taken of S5’s cooling tower that was serviced by ELECTROchem, and S4’s tower that was serviced by the existing chemical company.

Enclosed are ELECTROchem’s monthly service reports and corrosion coupon results (mild steel and copper) for S5, along with monthly water analysis and biologic testing.

Closed Loop Treatment Comparison

| NOTE 1: | See pictures of S4 condenser heat exchanger after tubes were punched in 2008 prior to ELECTROchem. System was on 100% chemical treatment at that time. |

| NOTE 2: | ALL PICTURES WERE TAKEN FROM THE TOP EXIT TUBES OF THE CONDENSER. |

| NOTE 3: | The following pictures represent a minimum of 10% energy savings and 20% water savings, as well as the cost of punching chiller tubes. |

S-4 TUBES IN 2008 PRIOR TO ELECTROchem INSTALLATION

S-4 ELECTROchem + CHEMICALS (95% Scale Free)

S-10 100% Traditional Chemical System (Less than 50% Scale Free)

S-5 100% ELECTROchem System (99% Scale Free)

S-5 TOWER – 100% ELECTROchem Serviced

S-4 TOWER Serviced by Others (Chemically Treated)

CORROSION ANALYSIS DATA REPORT

ALLOY - C1010 -- MILD STEEL| Initial Weight | 11.6030 |

| Final Weight | 11.5553 |

| Weight Loss | 0.0477 |

| Density (g/cm3) | 7.8700 |

| ID # | B48021 |

| Installed | 07/08/09 |

| Removed | 10/09/09 |

| Hours Exposed | 2232 |

| Surface Area (in2) | 3.3785 |

| Mils Per Year | 0.4297 |

|---|

CORROSION ANALYSIS DATA REPORT

ALLOY - CDA110 COPPER| Initial Weight | 12.5963 |

| Final Weight | 12.5851 |

| Weight Loss | 0.0112 |

| Density (g/cm3) | 8.8900 |

| ID # | U3965 |

| Installed | 07/08/09 |

| Removed | 10/09/09 |

| Hours Exposed | 2232 |

| Surface Area (in2) | 3.3662 |

| Mils Per Year | 0.0896 |

|---|

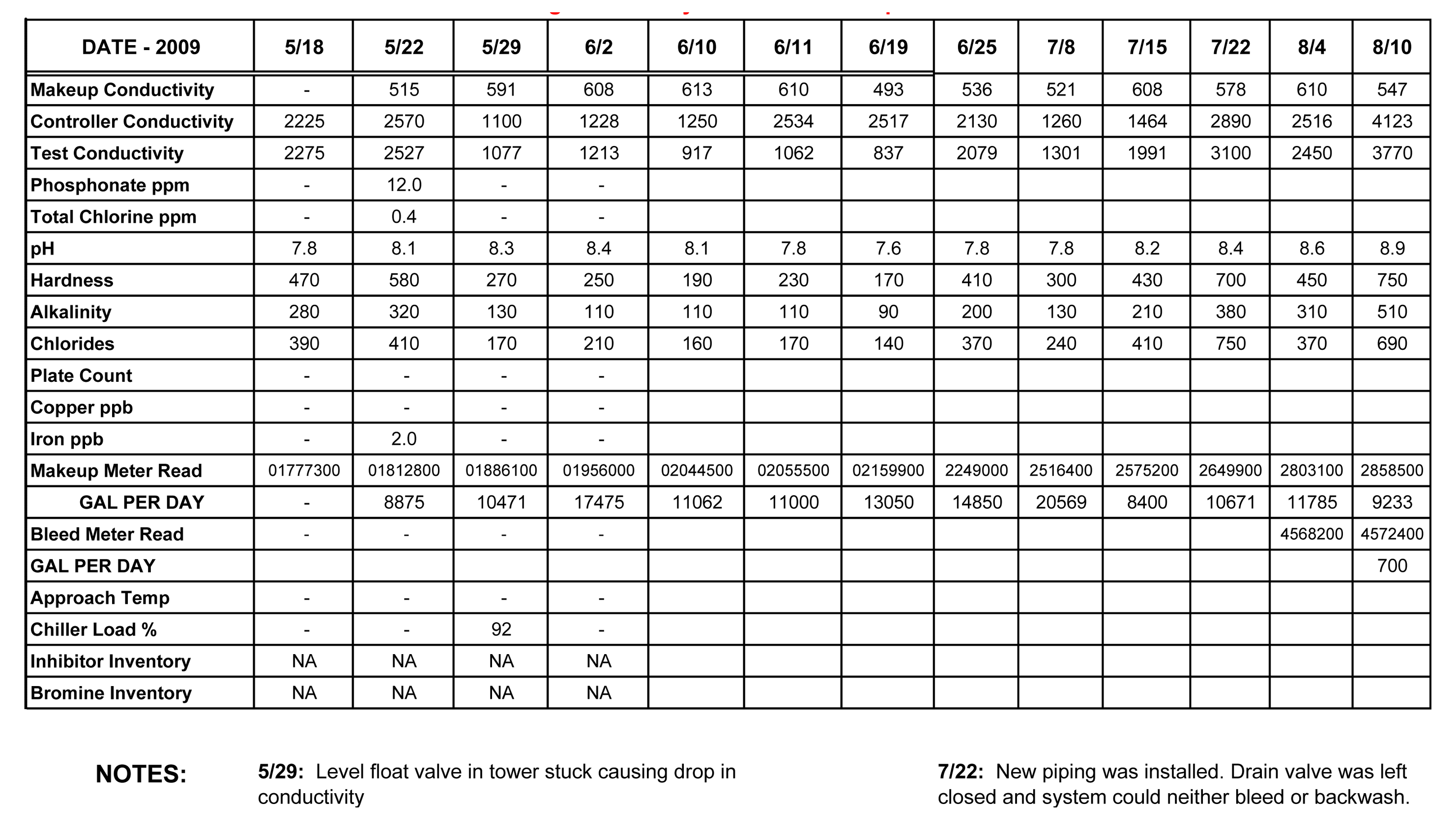

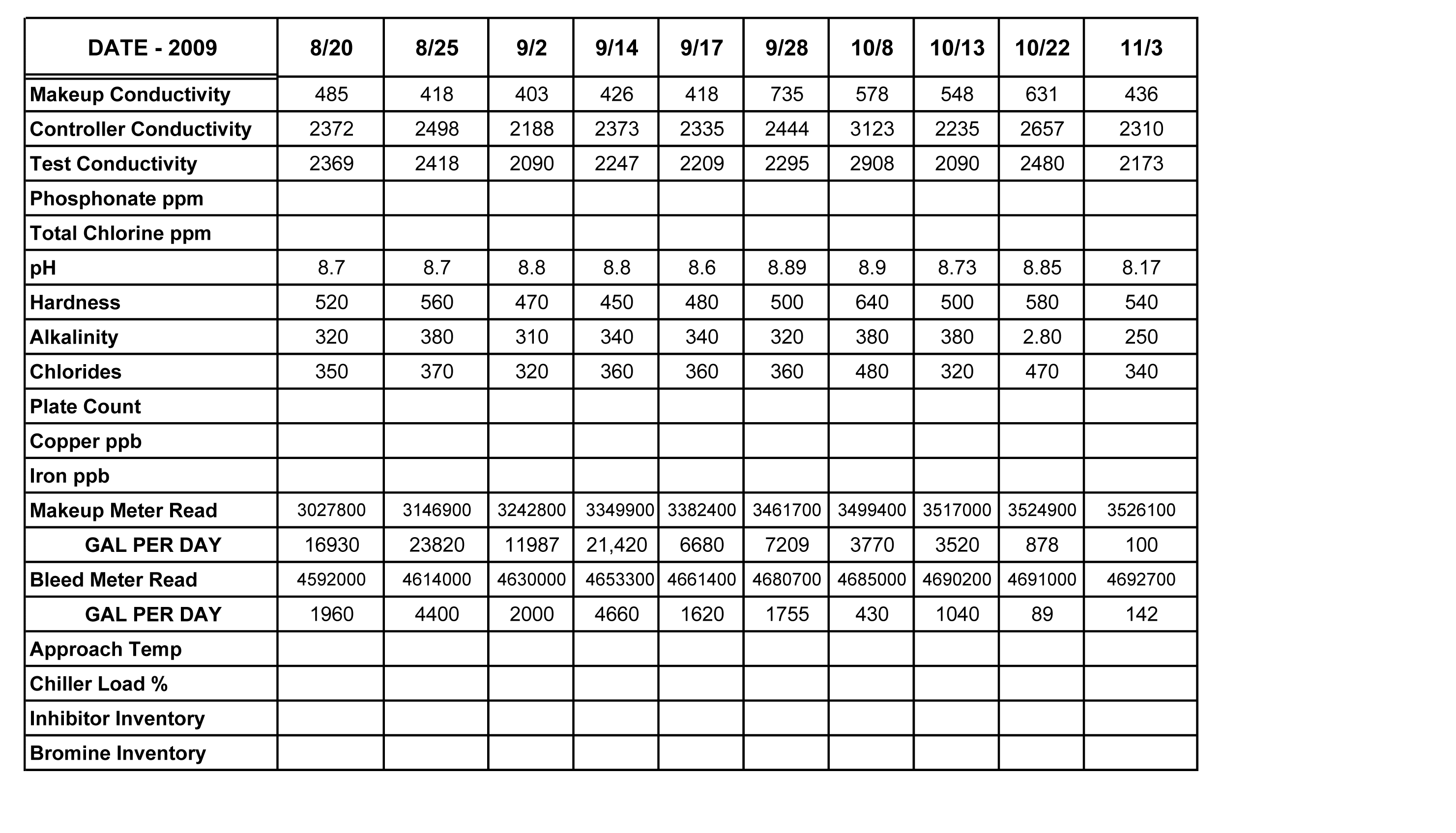

S-5 ELECTROchem TEST DATA (START: 5/18/09)

NOTE: ELECTROchem is total treatment program in this building